INDUSTRIES / Automotive / Oil Pump Assembly Line

Every customer that buys a new or used car assumes that engine components are the ones that have to last the longest. Not only because most of the times the spare parts are expensive, but nobody wants to come to an unwanted stop in the middle of nowhere. For that, integrated in-line testing of complex engine components becomes more important every day.

Engine Components in the car industry become more and more complex, as these components, better called subsystems, become controllable systems inside the engine. For example, oil pumps used to have a flow and pressure linear to the engine speed, but nowadays can be regulated to provide an optimal flow and pressure at all engine speeds.

This project concerns such an oil pump and not only does it assemble the oil pump with more than 50 single components, it has a complete test strategy to make sure that every single pump performs as it should.

|

||

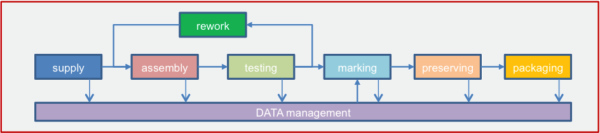

The assembly and test process of this sub system has been divided over 8 automatic machines and one in-line hand assembly. All decentralized stations with their own stand-alone control, but interconnected through a central transport system. This transport system not only ships the sub systems from station to station, but also gathers all assembly and test information in a RFID tag and finally stores it to a unique laser engraved Data Matrix Code.

|

||

Key words:

- - Laser engraving with integrated DMC check

- - Vibrational feeders

- - Tray Palletizers

- - Spring feeders

- - Pressure and Flow measurement

- - Leakage testing

- - Force and way controlled Presses

- - Torque and revolution controlled tighteners

- - In-line hand assembly of valve and cable

- - RFID data handling

- - Camera inspection

- - 750.000 parts per year

- - 27 seconds cycle time

For more information please contact our Sales

Call +31 45 543 9251 or e-mail sales@gdo-bv.com